Home>Culinary & Beverages>When To Check The Temperature Of Food During Receiving

Culinary & Beverages

When To Check The Temperature Of Food During Receiving

Published: March 3, 2024

Learn when to check the temperature of food during receiving and ensure food safety in the culinary and beverages industry. Understand the critical points for temperature monitoring.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Temperatures.com, at no extra cost. Learn more)

Table of Contents

Importance of Temperature Checking

Temperature checking during food receiving is a critical step in ensuring food safety and quality. It serves as a fundamental measure to prevent the risk of foodborne illnesses and maintain the integrity of perishable items. By meticulously monitoring the temperature of incoming food products, food establishments can uphold regulatory compliance and safeguard the well-being of their patrons.

When food items are delivered, their temperatures must be promptly assessed to verify that they fall within the recommended safe range. This practice is especially crucial for perishable goods such as meat, poultry, seafood, dairy products, and ready-to-eat foods. These items are susceptible to bacterial growth and contamination when exposed to temperatures outside the safe zone. Therefore, conducting temperature checks at the point of receiving is an indispensable preemptive measure.

In addition to food safety considerations, temperature checking also directly impacts the overall quality and freshness of the received products. For instance, maintaining the ideal temperature for perishable goods helps preserve their texture, flavor, and nutritional value. By promptly identifying any deviations from the optimal temperature range, food establishments can take proactive measures to mitigate potential quality issues and uphold the standards of their offerings.

Furthermore, temperature checking plays a pivotal role in upholding regulatory standards and compliance with food safety guidelines. Adhering to these standards not only mitigates the risk of foodborne illnesses but also fosters trust and confidence among consumers. It demonstrates a commitment to upholding stringent food safety protocols, thereby enhancing the reputation and credibility of the establishment.

In essence, the importance of temperature checking during food receiving cannot be overstated. It is a foundational practice that underpins food safety, quality assurance, and regulatory compliance. By diligently monitoring the temperatures of incoming food items, establishments can mitigate the risk of foodborne illnesses, preserve product quality, and demonstrate their unwavering commitment to upholding the highest standards of food safety and hygiene.

Recommended Temperature Range for Different Types of Food

Ensuring that different types of food are stored and received at the appropriate temperatures is paramount for maintaining food safety and quality. The recommended temperature ranges for various food categories are established based on scientific research and regulatory guidelines. By adhering to these guidelines, food establishments can mitigate the risk of bacterial growth, preserve the freshness of perishable items, and uphold the integrity of their offerings.

-

Meat and Poultry:

- Fresh beef, pork, lamb: 40°F (4°C) or below

- Ground meats: 40°F (4°C) or below

- Poultry: 40°F (4°C) or below

-

Seafood:

- Fish: 32°F (0°C) to 38°F (3.3°C)

- Shellfish: 32°F (0°C) to 45°F (7.2°C)

-

Dairy Products:

- Milk: 45°F (7.2°C) or below

- Cheese: 35°F (1.6°C) to 45°F (7.2°C)

-

Ready-to-Eat Foods:

- Deli meats: 40°F (4°C) or below

- Prepackaged salads: 40°F (4°C) or below

- Cooked foods: 135°F (57.2°C) or above

-

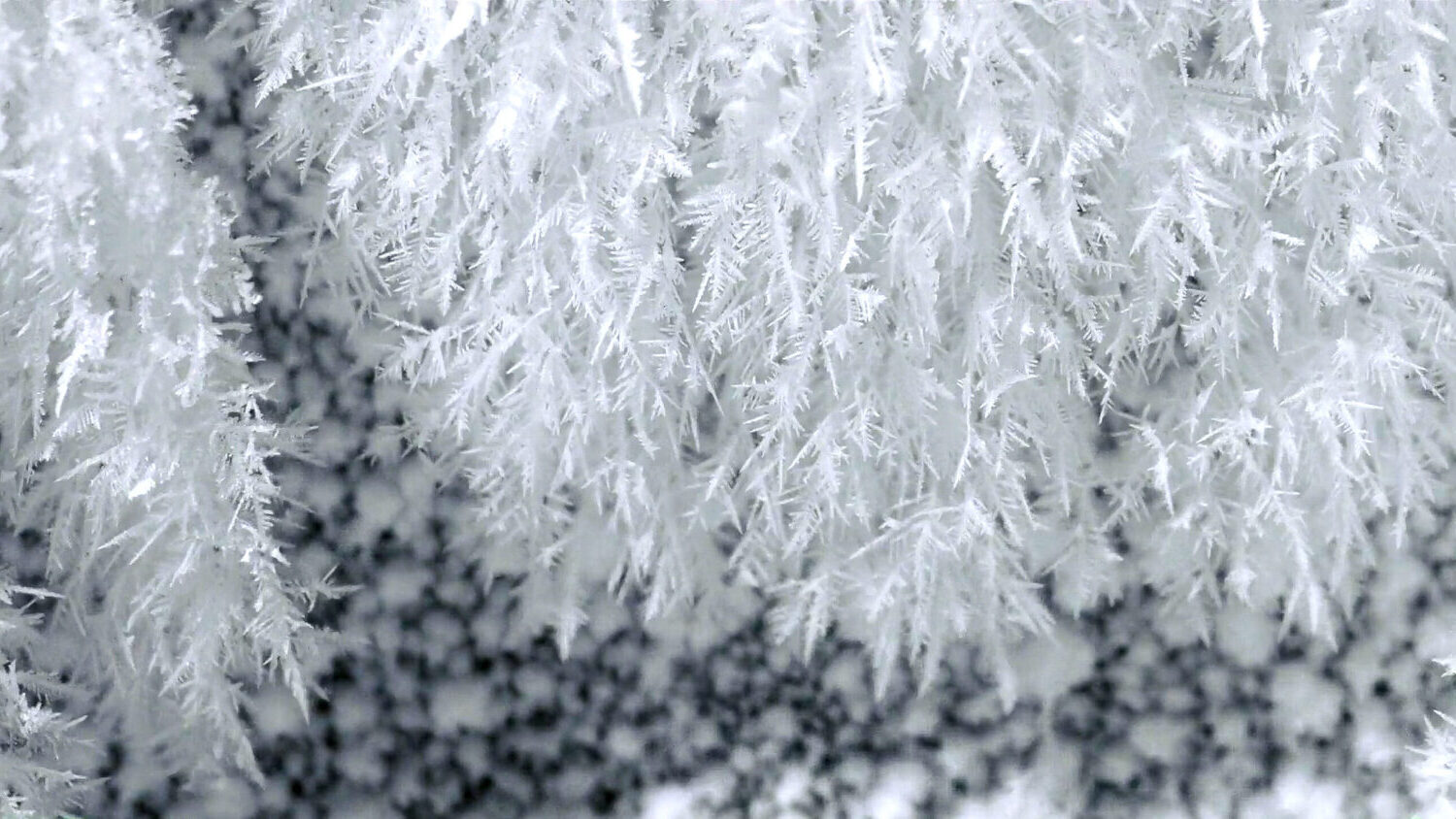

Frozen Foods:

- Frozen meats and seafood: 0°F (-17.8°C) or below

- Frozen fruits and vegetables: 0°F (-17.8°C) or below

Adhering to these recommended temperature ranges is essential for preventing the proliferation of harmful bacteria and maintaining the quality of perishable items. For instance, storing meat and poultry at temperatures above 40°F (4°C) can create an environment conducive to bacterial growth, increasing the risk of foodborne illnesses. Similarly, seafood must be stored at near-freezing temperatures to preserve its freshness and prevent spoilage.

Furthermore, maintaining the appropriate temperature range for dairy products is crucial for preventing spoilage and maintaining their nutritional value. Deviations from the recommended temperature ranges can lead to accelerated spoilage, affecting the taste, texture, and safety of these products.

When receiving ready-to-eat foods, it is imperative to ensure that they are maintained at the recommended temperatures to prevent the proliferation of pathogens. This is particularly important for cooked foods, as they must be stored above 135°F (57.2°C) to inhibit bacterial growth and ensure food safety.

In the case of frozen foods, maintaining temperatures at or below 0°F (-17.8°C) is essential for preserving the quality and integrity of the products. Any fluctuations in temperature can compromise the texture and flavor of frozen items, leading to potential quality issues.

In summary, understanding and adhering to the recommended temperature ranges for different types of food is fundamental to ensuring food safety, preventing spoilage, and upholding the quality of perishable items. By meticulously monitoring and maintaining the appropriate temperatures during food receiving and storage, food establishments can mitigate the risk of foodborne illnesses, preserve product quality, and demonstrate their commitment to upholding the highest standards of food safety and hygiene.

Potential Risks of Accepting Food at Incorrect Temperatures

Accepting food at incorrect temperatures poses significant risks to both food safety and quality. When perishable items such as meat, poultry, seafood, and dairy products are received at temperatures outside the recommended range, several potential hazards emerge, jeopardizing the well-being of consumers and the reputation of food establishments.

One of the primary risks associated with accepting food at incorrect temperatures is the proliferation of harmful bacteria. Perishable items that are stored or transported at temperatures higher than the recommended range create an environment conducive to bacterial growth. Bacteria such as Salmonella, E. coli, and Listeria monocytogenes thrive in conditions where temperatures allow for rapid multiplication. When consumers are exposed to food contaminated with these pathogens, the risk of foodborne illnesses significantly increases, leading to potential health complications and legal ramifications for the food establishment.

Moreover, accepting food at incorrect temperatures can compromise the sensory attributes and nutritional quality of perishable items. For instance, when dairy products are exposed to temperatures above the recommended range, the integrity of their texture, flavor, and nutritional content may be compromised. This can result in accelerated spoilage, off-flavors, and reduced shelf life, ultimately impacting consumer satisfaction and the reputation of the establishment.

In addition, the financial implications of accepting food at incorrect temperatures cannot be overlooked. Food establishments may incur significant losses if perishable items are received at improper temperatures, leading to increased food waste and potential liabilities. Furthermore, the costs associated with mitigating the consequences of accepting such food, including disposal, reordering, and potential legal fees, can exert a substantial financial burden on the establishment.

Furthermore, regulatory non-compliance is a critical risk associated with accepting food at incorrect temperatures. Health and safety regulations mandate that perishable items must be stored and received within specified temperature ranges to ensure consumer protection. Failure to adhere to these regulations can result in fines, penalties, and reputational damage, tarnishing the credibility of the establishment and eroding consumer trust.

In summary, the potential risks of accepting food at incorrect temperatures encompass a broad spectrum of concerns, ranging from compromised food safety and quality to financial and regulatory implications. By understanding these risks and implementing stringent temperature monitoring practices during food receiving, food establishments can mitigate these potential hazards, safeguard consumer well-being, and uphold the highest standards of food safety and hygiene.

Best Practices for Temperature Checking During Receiving

When it comes to ensuring food safety and quality, implementing best practices for temperature checking during receiving is paramount. By adhering to rigorous protocols and guidelines, food establishments can mitigate the risk of foodborne illnesses, preserve the integrity of perishable items, and uphold regulatory compliance. The following best practices serve as foundational principles for effective temperature checking during the receiving process:

-

Establish Standard Operating Procedures (SOPs): Developing comprehensive SOPs for temperature checking during receiving is essential. These SOPs should outline the specific protocols for inspecting the temperatures of incoming food items, including the frequency of checks, designated personnel responsible for the task, and the use of calibrated thermometers.

-

Train Personnel: Providing thorough training to staff members involved in the receiving process is crucial. Training should encompass proper temperature measurement techniques, thermometer usage, and the importance of accurate record-keeping. Equipping personnel with the necessary knowledge and skills empowers them to execute temperature checks with precision and consistency.

-

Use Reliable Thermometers: Utilizing calibrated and reliable food thermometers is non-negotiable. Digital thermometers with accurate probes are recommended for obtaining precise temperature readings. Regular calibration and maintenance of thermometers are imperative to ensure their accuracy and reliability.

-

Implement Visual Inspection: In addition to temperature checks, conducting visual inspections of incoming food items is essential. This includes assessing the overall condition of perishable products, verifying packaging integrity, and identifying any signs of potential temperature abuse or contamination.

-

Document Temperature Records: Maintaining meticulous records of temperature checks is a fundamental practice. Establishments should diligently document temperature readings, including the time of inspection, the name of the person conducting the check, and the details of the received items. These records serve as crucial documentation for regulatory compliance and quality assurance.

-

Establish Rejection Criteria: Clearly defining criteria for rejecting food items based on temperature deviations is imperative. Establishments should establish predetermined temperature thresholds beyond which incoming products are deemed unacceptable. This proactive approach ensures that potentially hazardous items are promptly identified and addressed.

-

Facilitate Rapid Cooling: If perishable items are received at temperatures slightly above the recommended range, implementing rapid cooling measures is essential. This may involve promptly transferring the items to refrigeration or cold storage facilities to mitigate any potential temperature abuse during transit.

By adhering to these best practices, food establishments can fortify their temperature checking protocols during the receiving process, thereby enhancing food safety, quality assurance, and regulatory compliance. These practices serve as proactive measures to mitigate the risk of accepting food at incorrect temperatures, ultimately safeguarding consumer well-being and upholding the highest standards of food safety and hygiene.

How to Use a Food Thermometer Correctly

Using a food thermometer correctly is a fundamental aspect of ensuring food safety and quality in any culinary setting. By employing precise techniques and adhering to best practices, food establishments can accurately assess the internal temperatures of various food items, thereby mitigating the risk of foodborne illnesses and upholding regulatory compliance. The following guidelines outline the essential steps for utilizing a food thermometer correctly:

-

Select the Appropriate Thermometer: Choosing the right type of food thermometer is the first step in ensuring accurate temperature measurements. Digital probe thermometers are versatile and suitable for a wide range of food items, providing quick and precise readings. For thin foods such as burgers or fish fillets, consider using a thermocouple thermometer for rapid and accurate results.

-

Calibrate the Thermometer: Before each use, it is crucial to calibrate the food thermometer to verify its accuracy. This can be achieved by immersing the thermometer probe in a mixture of ice and water, ensuring that it registers a temperature of 32°F (0°C). If the thermometer does not display this temperature, it may require recalibration or adjustment.

-

Proper Insertion Technique: When measuring the temperature of food items, the thermometer probe should be inserted into the thickest part of the item, away from any bones, fat, or gristle. For example, when checking the doneness of a roast chicken, insert the thermometer into the innermost part of the thigh without touching the bone for an accurate reading.

-

Wait for Stabilization: After inserting the thermometer probe, allow sufficient time for the temperature reading to stabilize. This is particularly important for thicker cuts of meat or large food items. Waiting for the reading to stabilize ensures that an accurate internal temperature is obtained, reflecting the true doneness of the food.

-

Multiple Measurement Points: For larger food items such as roasts or whole poultry, consider taking temperature measurements at multiple points to ensure uniform doneness. This practice helps identify any potential temperature differentials within the item, providing a comprehensive assessment of its overall doneness and safety.

-

Cleaning and Sanitization: Proper hygiene and sanitation of the food thermometer are essential. After each use, thoroughly clean the thermometer probe with hot, soapy water and sanitize it to prevent cross-contamination. This practice ensures the integrity of temperature measurements and prevents the spread of harmful bacteria.

By adhering to these guidelines and incorporating them into standard operating procedures, food establishments can effectively utilize food thermometers to ensure the safety and quality of their offerings. Accurate temperature measurements not only mitigate the risk of foodborne illnesses but also contribute to the overall satisfaction and confidence of consumers in the establishment's commitment to food safety and hygiene.