Home>Science & Environment>Thermometers For Measuring Surface Temperatures

Science & Environment

Thermometers For Measuring Surface Temperatures

Published: February 19, 2024

Shop a wide selection of thermometers for measuring surface temperatures in the Science & Environment category. Find the perfect tool for your needs today!

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Temperatures.com, at no extra cost. Learn more)

Table of Contents

Introduction

Surface thermometers play a crucial role in various fields, including science, engineering, and environmental monitoring. These specialized instruments are designed to measure the temperature of surfaces accurately, providing valuable data for a wide range of applications. Whether it's monitoring the temperature of industrial equipment, conducting scientific research, or ensuring food safety, surface thermometers are indispensable tools that offer precise temperature readings.

In scientific research, surface thermometers are utilized to measure the temperature of natural surfaces such as soil, water bodies, and vegetation. This data is essential for understanding ecological processes, climate patterns, and the impact of human activities on the environment. Furthermore, in the field of engineering, surface thermometers are instrumental in assessing the performance and safety of machinery, ensuring that critical components operate within specified temperature ranges to prevent malfunctions and potential hazards.

Moreover, in the realm of food safety and culinary arts, surface thermometers are employed to verify the temperature of cooking surfaces, ensuring that food is prepared and stored at safe temperatures to prevent the growth of harmful bacteria. This is particularly crucial in commercial kitchens, where adherence to strict temperature guidelines is essential to prevent foodborne illnesses and maintain high standards of hygiene.

In this comprehensive guide, we will explore the different types of surface thermometers, factors to consider when choosing the most suitable instrument for specific applications, best practices for accurate temperature measurements, and the diverse applications of surface thermometers across various industries. By delving into these aspects, readers will gain a deeper understanding of the significance of surface thermometers and their pivotal role in ensuring precision, safety, and efficiency in a multitude of endeavors.

Types of Surface Thermometers

Surface thermometers are designed to measure the temperature of solid objects, liquids, or gases that are not in direct contact with the thermometer. These specialized instruments come in various types, each tailored to specific applications and environmental conditions. Understanding the different types of surface thermometers is essential for selecting the most suitable device for a particular task. Here are some common types of surface thermometers:

-

Infrared Thermometers: Also known as IR thermometers or non-contact thermometers, these devices measure temperature from a distance by detecting the infrared energy emitted by an object. They are widely used in industrial settings, food processing, and medical applications due to their non-invasive nature and rapid temperature readings.

-

Surface Probe Thermometers: These thermometers feature a metal probe that is placed directly on the surface to be measured. They are ideal for applications where direct contact with the surface is feasible, such as monitoring the temperature of grills, cooking surfaces, and industrial machinery.

-

Thermocouple Surface Thermometers: Utilizing the principle of thermoelectricity, thermocouple surface thermometers consist of two different metal wires joined at one end. When the measurement end is placed on a surface, a temperature-dependent voltage is generated, allowing for accurate temperature readings.

-

Resistance Temperature Detectors (RTDs): RTD surface thermometers are designed with a temperature-sensitive resistor that changes resistance with temperature variations. They offer high accuracy and stability, making them suitable for precise temperature measurements in scientific research and industrial processes.

-

Liquid Crystal Thermometers: These thermometers contain heat-sensitive liquid crystals that change color based on the temperature of the surface they are applied to. While not as precise as other types, they are cost-effective and find applications in educational settings and quick temperature assessments.

-

Bimetallic Strip Thermometers: This type of surface thermometer utilizes the differential expansion of two metals bonded together. As the temperature changes, the metals expand or contract, causing the strip to bend. The degree of bending indicates the temperature of the surface.

Each type of surface thermometer offers distinct advantages and limitations, making it crucial to select the most suitable instrument based on the specific requirements of the intended application. By understanding the characteristics and functionalities of these thermometers, professionals can make informed decisions to ensure accurate temperature measurements in diverse settings.

Factors to Consider When Choosing a Surface Thermometer

When selecting a surface thermometer for a particular application, several crucial factors must be taken into account to ensure accurate temperature measurements and optimal performance. Understanding these considerations is essential for professionals across various industries to make informed decisions when choosing the most suitable instrument. The following factors play a pivotal role in the selection process:

-

Accuracy and Precision: One of the primary considerations when choosing a surface thermometer is its accuracy and precision. The instrument must provide reliable temperature readings within the required range to meet the specific needs of the application. High-precision thermometers are essential for scientific research, industrial processes, and quality control in manufacturing.

-

Temperature Range: Different surface thermometers are designed to measure specific temperature ranges. It is crucial to select a thermometer that can effectively capture the range of temperatures relevant to the application. For instance, industrial processes may require thermometers capable of measuring extremely high or low temperatures, while culinary applications may focus on a narrower temperature range.

-

Response Time: The response time of a surface thermometer, or the time it takes to display an accurate temperature reading after being placed on a surface, is critical in dynamic environments. In applications where rapid temperature changes occur, such as in industrial processes or HVAC systems, a fast-response thermometer is essential to capture real-time temperature fluctuations.

-

Environmental Conditions: The environmental conditions in which the surface thermometer will be used must be carefully considered. Factors such as humidity, dust, and exposure to chemicals or corrosive substances can impact the performance and longevity of the instrument. Selecting a thermometer with suitable environmental protection and durability is crucial for reliable operation in challenging settings.

-

Calibration and Maintenance: Regular calibration and maintenance are essential to ensure the accuracy and reliability of surface thermometers. Choosing instruments that are easy to calibrate and maintain, or ones that come with calibration certificates, can streamline the upkeep process and contribute to consistent and precise temperature measurements over time.

-

Application-Specific Features: Different applications may require specific features in a surface thermometer. For example, in food safety, a thermometer with a built-in timer and alarm for temperature thresholds may be advantageous. In scientific research, compatibility with data logging and analysis systems may be a crucial consideration.

-

Budget and Cost of Ownership: The initial cost of a surface thermometer, as well as the long-term cost of ownership including maintenance, calibration, and potential replacement, should be factored into the decision-making process. Balancing the budget with the required features and performance is essential to make a cost-effective investment.

By carefully considering these factors, professionals can make informed decisions when choosing a surface thermometer, ensuring that the selected instrument meets the specific requirements of the application, delivers accurate temperature measurements, and operates effectively in the intended environment.

Best Practices for Measuring Surface Temperatures

Accurate measurement of surface temperatures is essential across various industries and scientific disciplines. To ensure precise and reliable temperature readings, it is imperative to adhere to best practices when using surface thermometers. By following established guidelines and implementing proper techniques, professionals can optimize the accuracy of temperature measurements and enhance the effectiveness of their operations. Here are the best practices for measuring surface temperatures:

-

Proper Instrument Selection: Selecting the most suitable surface thermometer for the specific application is the first step towards accurate temperature measurements. Consider the type of surface to be measured, the temperature range, environmental conditions, and required precision when choosing the instrument.

-

Calibration and Verification: Regular calibration of surface thermometers is crucial to maintain accuracy. Verify the calibration of the instrument before each use, especially if it has been exposed to extreme conditions or has not been used for an extended period. This ensures that the thermometer provides reliable readings.

-

Correct Placement: Proper placement of the thermometer on the surface being measured is essential. Ensure that the entire sensing area of the thermometer makes direct contact with the surface, especially for surface probe thermometers. For infrared thermometers, maintain the recommended distance and angle for accurate readings.

-

Stabilization Time: Allow the surface thermometer to stabilize and equilibrate with the surface temperature before recording the reading. This is particularly important when measuring surfaces with rapid temperature changes or when using thermocouple or RTD thermometers.

-

Avoiding Contamination: Prevent contamination of the thermometer and the surface being measured. Clean the sensing area of the thermometer before and after each use, especially when measuring food surfaces, to prevent cross-contamination and ensure hygienic practices.

-

Environmental Considerations: Take into account the environmental conditions that may affect temperature measurements. Factors such as air currents, radiant heat sources, and ambient temperature variations can impact the accuracy of readings. Minimize environmental influences to obtain precise measurements.

-

Safety Precautions: When measuring surface temperatures in industrial settings, adhere to safety protocols and use appropriate personal protective equipment. Ensure that the surface being measured is safe to access and that the measurement process does not pose any risks to personnel or equipment.

-

Documentation and Record-Keeping: Maintain detailed records of temperature measurements, including the date, time, location, and any relevant environmental conditions. This documentation is valuable for quality control, compliance with regulations, and analysis of temperature trends over time.

By following these best practices, professionals can optimize the accuracy and reliability of surface temperature measurements, contributing to enhanced safety, quality control, and informed decision-making across diverse applications.

Applications of Surface Thermometers

Surface thermometers find extensive applications across diverse industries and scientific disciplines, playing a pivotal role in ensuring precision, safety, and efficiency in a multitude of endeavors. The versatility and accuracy of these instruments make them indispensable for various applications, ranging from industrial processes and engineering to scientific research, food safety, and environmental monitoring.

In industrial settings, surface thermometers are utilized for monitoring the temperature of machinery, equipment, and manufacturing processes. These instruments play a critical role in ensuring that components operate within specified temperature ranges to prevent malfunctions, optimize performance, and enhance operational safety. Surface thermometers are particularly valuable in industries such as metallurgy, automotive manufacturing, and electronics, where precise temperature control is essential for quality assurance and process optimization.

In the field of engineering, surface thermometers are instrumental in assessing the performance and safety of mechanical systems, engines, and industrial infrastructure. These instruments enable engineers to monitor the temperature of critical components, identify potential issues such as overheating or thermal stress, and implement proactive maintenance measures to prevent costly downtime and equipment failures.

Moreover, surface thermometers play a crucial role in food safety and culinary applications. In commercial kitchens, restaurants, and food processing facilities, these instruments are employed to verify the temperature of cooking surfaces, refrigeration units, and food storage areas. By ensuring that food is prepared, stored, and served at safe temperatures, surface thermometers contribute to preventing the growth of harmful bacteria, safeguarding public health, and maintaining high standards of hygiene in food handling and preparation.

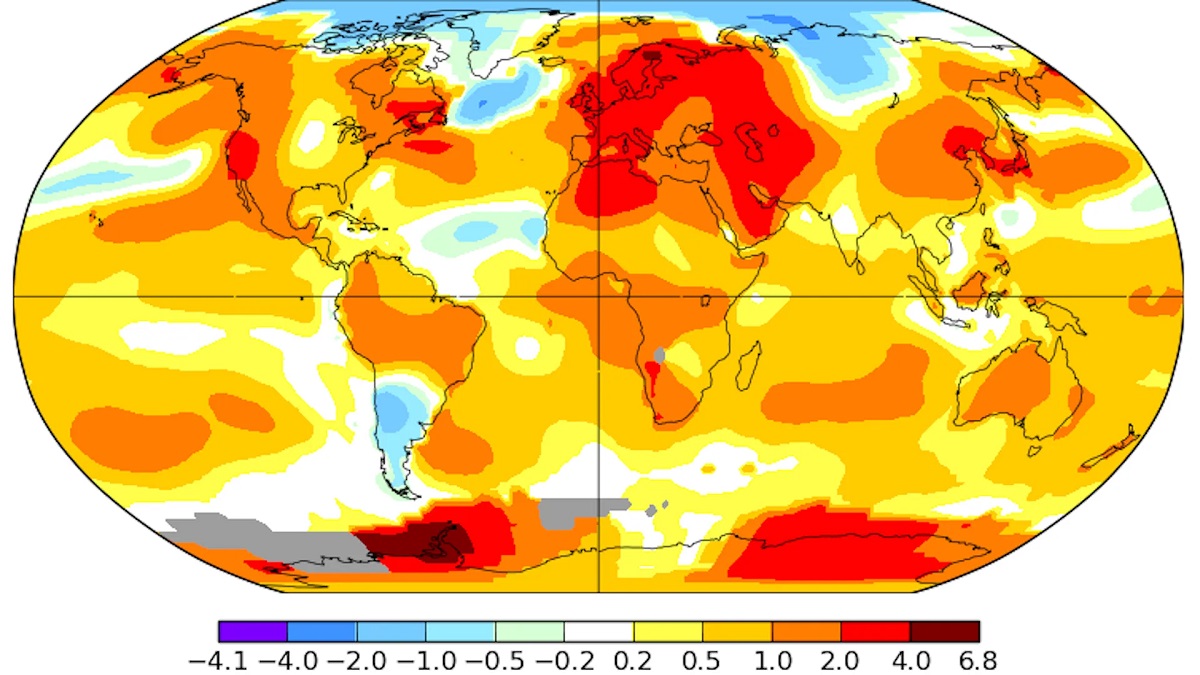

In scientific research and environmental monitoring, surface thermometers are used to measure the temperature of natural surfaces such as soil, water bodies, and vegetation. This data is essential for understanding ecological processes, climate patterns, and the impact of human activities on the environment. Surface thermometers are integral to studies on climate change, ecosystem dynamics, and agricultural practices, providing valuable insights into temperature variations and their implications for biodiversity, agriculture, and natural resource management.

Furthermore, in HVAC (Heating, Ventilation, and Air Conditioning) systems and building maintenance, surface thermometers are employed to assess the temperature of heating and cooling surfaces, detect thermal inefficiencies, and optimize energy usage. By identifying areas of heat loss or inadequate insulation, these instruments contribute to enhancing energy efficiency, reducing operational costs, and improving indoor comfort in residential, commercial, and industrial buildings.

The diverse applications of surface thermometers underscore their significance in ensuring operational efficiency, safety, and quality across a wide spectrum of industries and scientific disciplines. By providing accurate and reliable temperature measurements, these instruments contribute to informed decision-making, regulatory compliance, and the advancement of research and technological innovation.

Conclusion

In conclusion, surface thermometers are indispensable tools that play a pivotal role in diverse industries and scientific endeavors. These specialized instruments, ranging from infrared thermometers to surface probe thermometers, offer precise temperature measurements for a wide array of applications. The significance of surface thermometers is underscored by their contributions to industrial processes, engineering, food safety, scientific research, environmental monitoring, and HVAC systems.

The versatility of surface thermometers enables professionals to monitor and optimize temperature-related aspects critical to operational safety, quality control, and efficiency. From ensuring the safe operation of machinery in industrial settings to maintaining hygienic food preparation conditions in commercial kitchens, these instruments are essential for upholding stringent standards and regulatory compliance.

Furthermore, in scientific research and environmental monitoring, surface thermometers provide valuable insights into temperature variations across natural surfaces, contributing to a deeper understanding of ecological processes, climate dynamics, and the impact of human activities on the environment. This data is instrumental in addressing challenges related to climate change, biodiversity conservation, and sustainable resource management.

By adhering to best practices for measuring surface temperatures and considering factors such as accuracy, temperature range, response time, and environmental conditions when choosing a surface thermometer, professionals can ensure precise and reliable temperature measurements tailored to specific applications.

In essence, the applications of surface thermometers extend across a broad spectrum, encompassing critical functions in industrial operations, engineering assessments, food safety protocols, scientific research endeavors, environmental conservation efforts, and energy-efficient building management. The comprehensive understanding of surface thermometers and their optimal utilization is essential for driving innovation, ensuring safety, and fostering sustainable practices across various domains.

As technology continues to advance, surface thermometers are expected to evolve, offering enhanced precision, connectivity, and adaptability to meet the evolving needs of industries and scientific disciplines. The continued integration of surface thermometers into diverse applications underscores their enduring significance in facilitating informed decision-making, operational excellence, and the pursuit of sustainable and resilient systems.

In summary, surface thermometers stand as essential instruments that contribute to precision, safety, and efficiency across a multitude of endeavors, making them indispensable assets in the pursuit of excellence and innovation.