Home>Education & Research>Enzymes: Reusability And Benefits

Education & Research

Enzymes: Reusability And Benefits

Published: February 19, 2024

Discover the reusability and benefits of enzymes in education and research. Learn how enzymes contribute to sustainable practices and scientific advancements.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Temperatures.com, at no extra cost. Learn more)

Table of Contents

Introduction

Enzymes are remarkable biological molecules that serve as catalysts for a myriad of biochemical reactions within living organisms. These specialized proteins play a pivotal role in accelerating chemical reactions without being consumed in the process. Their ability to facilitate and expedite crucial cellular processes has garnered significant attention across various industries, including healthcare, food production, and environmental sustainability.

Enzymes are renowned for their unparalleled efficiency in catalyzing reactions, often resulting in a substantial reduction in the energy required for these processes to occur. This remarkable attribute has positioned enzymes as indispensable components in numerous industrial applications, where they contribute to enhancing productivity, reducing waste, and minimizing environmental impact.

Furthermore, the reusability of enzymes sets them apart from traditional chemical catalysts. Unlike conventional catalysts that often undergo irreversible changes during reactions, enzymes retain their structural integrity and functionality, allowing them to be utilized repeatedly. This inherent reusability not only contributes to cost-effectiveness but also aligns with the principles of sustainability by minimizing resource consumption and waste generation.

As we delve deeper into the mechanisms of enzyme reusability and explore their diverse industrial applications, it becomes evident that these biological catalysts hold immense potential for driving innovation and progress across various sectors. Moreover, the environmental benefits associated with the use of enzymes further underscore their significance in promoting eco-friendly practices and mitigating the impact of industrial activities on the planet.

In this article, we will embark on a comprehensive journey to unravel the intricacies of enzyme reusability, shedding light on their industrial applications, environmental advantages, as well as the challenges and limitations that accompany their widespread utilization. Through this exploration, we aim to gain a profound understanding of the multifaceted role played by enzymes in shaping modern industries and fostering sustainable practices.

The Mechanism of Enzyme Reusability

Enzyme reusability is a fundamental characteristic that distinguishes these biological catalysts from traditional chemical catalysts. Understanding the underlying mechanisms that enable enzymes to be utilized repeatedly provides valuable insights into their practical applications and environmental impact.

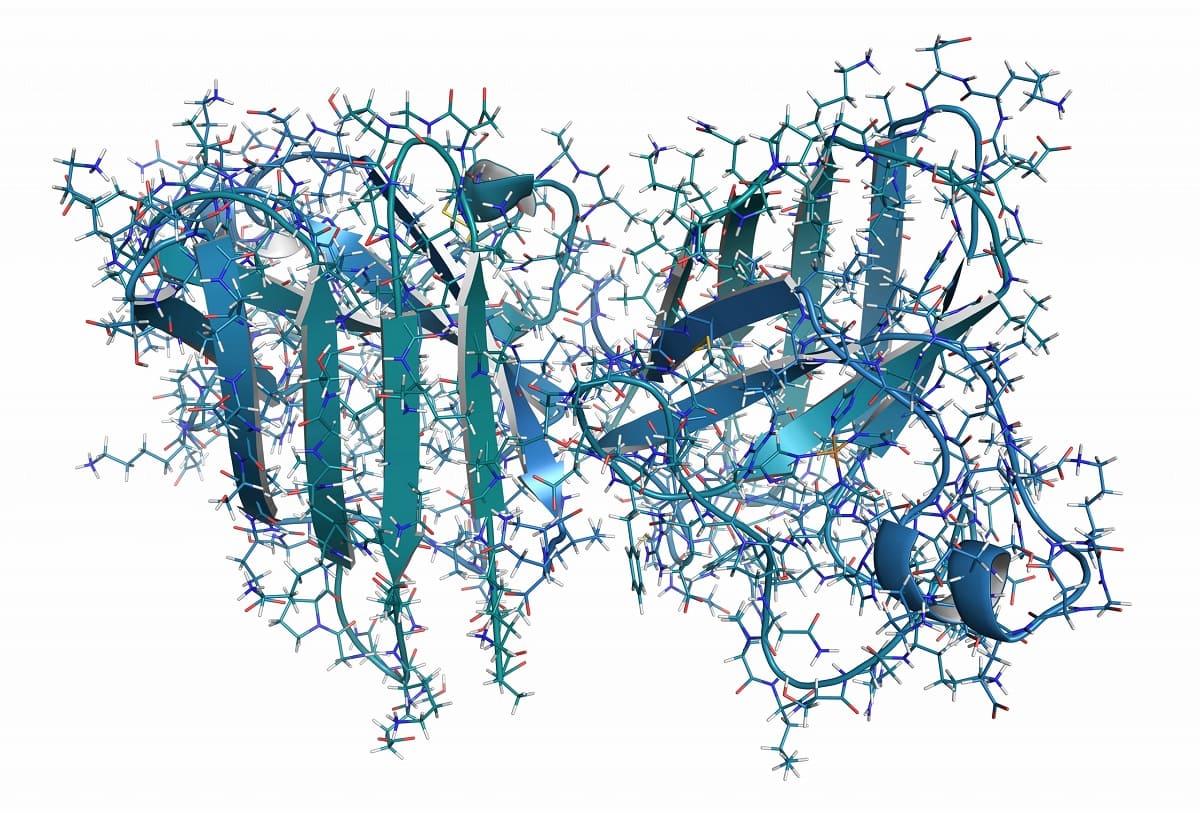

At the core of enzyme reusability lies the structural integrity and specificity of these biomolecules. Enzymes possess a unique three-dimensional structure, often likened to a lock-and-key model, where the enzyme (the lock) selectively binds to its substrate (the key) to initiate and facilitate a specific chemical reaction. This precise binding mechanism is governed by the complementary shapes and chemical properties of the enzyme and its substrate, ensuring a high degree of specificity in catalyzing reactions.

Upon catalyzing a reaction, enzymes remain structurally unchanged and unaltered by the process. Unlike conventional chemical catalysts that may undergo permanent alterations or become consumed during reactions, enzymes emerge from the reaction unscathed, ready to engage in subsequent catalytic activities. This inherent stability and resilience allow enzymes to be recovered from reaction mixtures and reused in subsequent cycles, thereby minimizing the need for frequent replenishment and reducing overall resource consumption.

Furthermore, the regulatory mechanisms that govern enzyme activity contribute to their reusability. Enzymes are subject to intricate regulatory processes, including feedback inhibition and allosteric regulation, which modulate their activity in response to changes in substrate concentration and cellular conditions. These regulatory mechanisms ensure that enzymes maintain optimal activity levels while avoiding overconsumption or depletion, thereby prolonging their functional lifespan and enabling repeated utilization in various reaction environments.

In industrial settings, the reusability of enzymes translates into tangible benefits, including cost savings and enhanced process efficiency. By harnessing the reusability of enzymes, industries can streamline production processes, minimize waste generation, and reduce the overall environmental footprint of their operations. Additionally, the ability to recover and reuse enzymes aligns with the principles of sustainable manufacturing, promoting resource conservation and eco-friendly practices.

In essence, the mechanism of enzyme reusability stems from the inherent stability, specificity, and regulatory control exhibited by these biological catalysts. By leveraging these unique attributes, industries can harness the full potential of enzymes to drive innovation, improve productivity, and foster sustainable practices that benefit both the economy and the environment.

Industrial Applications of Enzymes

The industrial applications of enzymes span a diverse array of sectors, showcasing the versatility and efficacy of these biological catalysts in driving innovation and efficiency. From food and beverage production to pharmaceutical manufacturing and biofuel development, enzymes play a pivotal role in optimizing processes, enhancing product quality, and minimizing environmental impact.

Food and Beverage Industry

Enzymes are widely employed in the food and beverage industry to facilitate various processes, including the production of bread, cheese, beer, and fruit juices. In baking, enzymes such as amylases and proteases aid in dough conditioning and gluten modification, leading to improved texture and volume in bread. Similarly, enzymes contribute to cheese ripening, where they break down proteins and fats to develop distinct flavors and textures. In brewing and fruit juice extraction, enzymes assist in the breakdown of starches and pectins, facilitating the release of sugars and enhancing the yield and quality of the final products.

Textile and Leather Processing

Enzymes find extensive use in textile and leather processing, offering sustainable alternatives to traditional chemical treatments. In textile manufacturing, enzymes are employed for desizing, bio-polishing, and denim finishing, leading to reduced water consumption, energy savings, and improved fabric quality. Similarly, in leather processing, enzymes aid in dehairing, bating, and degreasing, replacing harsh chemicals and promoting eco-friendly practices.

Biofuel Production

The production of biofuels, such as ethanol and biodiesel, relies on enzymes to convert biomass into fermentable sugars and fatty acids. Enzymes, including cellulases and lipases, play a crucial role in breaking down plant-derived materials into simple sugars and fatty acids, which can then be fermented into biofuels. This enzymatic approach offers a sustainable and renewable pathway for biofuel production, reducing reliance on fossil fuels and mitigating greenhouse gas emissions.

Pharmaceutical and Biotechnology

Enzymes are indispensable in pharmaceutical and biotechnological applications, where they are utilized in drug synthesis, diagnostic assays, and biocatalysis. Enzymes serve as catalysts in the synthesis of pharmaceutical compounds, enabling precise and efficient reactions while minimizing the generation of unwanted by-products. Moreover, enzymes play a vital role in diagnostic tests, such as enzyme-linked immunosorbent assays (ELISA), where they enable the detection of specific biomarkers and pathogens with high sensitivity and accuracy.

Waste Management and Environmental Remediation

Enzymes contribute to waste management and environmental remediation efforts by facilitating the degradation of organic pollutants and the treatment of wastewater. Enzymes, including peroxidases and oxidoreductases, are harnessed for the bioremediation of contaminated sites, where they aid in the breakdown of hazardous compounds and the restoration of environmental quality. Additionally, enzymes are utilized in wastewater treatment plants to enhance the decomposition of organic matter, leading to improved water quality and reduced environmental impact.

In summary, the industrial applications of enzymes encompass a wide spectrum of sectors, ranging from food and beverage production to waste management and environmental remediation. By harnessing the catalytic prowess and reusability of enzymes, industries can optimize processes, reduce resource consumption, and advance sustainable practices, thereby contributing to a more efficient and environmentally conscious industrial landscape.

Environmental Benefits of Enzymes

Enzymes offer a multitude of environmental benefits across various industrial and remediation applications, playing a pivotal role in promoting sustainability and minimizing the ecological footprint of human activities. These environmental advantages stem from the inherent characteristics of enzymes, including their biodegradability, specificity, and reusability, which collectively contribute to mitigating environmental impact and fostering eco-friendly practices.

Biodegradation and Pollution Remediation

One of the prominent environmental benefits of enzymes lies in their ability to facilitate the biodegradation of organic pollutants and contaminants. Enzymes, such as lipases, proteases, and cellulases, are adept at breaking down complex organic compounds into simpler, environmentally benign substances. This enzymatic degradation process aids in the remediation of contaminated soil and water, contributing to the restoration of ecosystems impacted by industrial activities, agricultural runoff, and accidental spills. By accelerating the natural breakdown of pollutants, enzymes offer a sustainable and cost-effective approach to environmental remediation, minimizing the long-term adverse effects of pollution on ecosystems and human health.

Reduced Chemical Usage and Waste Generation

In industrial processes, the utilization of enzymes often leads to a reduction in the overall consumption of harsh chemicals and the generation of hazardous waste. Enzymes serve as eco-friendly alternatives to traditional chemical treatments, particularly in sectors such as textile processing, pulp and paper production, and wastewater treatment. By replacing chemical-intensive processes with enzymatic treatments, industries can significantly decrease their reliance on environmentally harmful substances, thereby lowering the risk of chemical pollution and minimizing the environmental burden associated with waste disposal. Furthermore, the reusability of enzymes further amplifies their environmental benefits by reducing the need for frequent replenishment and minimizing resource consumption, aligning with the principles of sustainable resource management.

Energy Efficiency and Carbon Footprint Reduction

Enzymes contribute to energy efficiency and carbon footprint reduction by optimizing industrial processes and promoting sustainable production methods. In sectors such as biofuel production and biorefining, enzymes play a crucial role in converting biomass into renewable fuels and biochemicals, offering a sustainable alternative to fossil fuel-derived products. By enabling the efficient breakdown of biomass and the production of biofuels through enzymatic catalysis, industries can reduce their reliance on non-renewable resources, decrease greenhouse gas emissions, and mitigate the environmental impact associated with conventional fuel production. Additionally, the use of enzymes in energy-efficient processes, such as biogas production and bio-based material synthesis, further underscores their role in advancing environmentally conscious practices and fostering a greener industrial landscape.

In essence, the environmental benefits of enzymes encompass a wide spectrum of applications, ranging from pollution remediation and waste reduction to energy efficiency and sustainable production. By harnessing the catalytic prowess and eco-friendly attributes of enzymes, industries can contribute to a more sustainable and environmentally conscious approach to industrial operations, thereby fostering a harmonious coexistence with the natural world.

Challenges and Limitations of Enzyme Reusability

While the reusability of enzymes presents significant advantages in industrial and environmental applications, it is essential to acknowledge the challenges and limitations associated with this characteristic. Understanding these constraints is crucial for optimizing the utilization of enzymes and addressing potential hurdles that may arise in practical implementation.

Stability and Operational Conditions

Enzyme reusability is contingent upon maintaining the structural and functional integrity of the enzymes over multiple reaction cycles. However, certain operational conditions, such as extreme pH levels, high temperatures, or the presence of inhibitory substances, can compromise the stability and activity of enzymes. These factors may lead to enzyme denaturation, reduced catalytic efficiency, or loss of specificity, ultimately impacting their reusability. Addressing the stability of enzymes under diverse operational conditions is a key challenge in maximizing their reusability across different industrial processes.

Immobilization and Reactor Design

The immobilization of enzymes onto solid supports or within matrices is a common strategy to facilitate their recovery and reuse in continuous or batch processes. However, the immobilization process itself can pose challenges, including the potential loss of enzyme activity, mass transfer limitations, and limited accessibility of substrates to the immobilized enzymes. Moreover, the design of enzyme reactors and the selection of suitable immobilization techniques are critical considerations in ensuring the efficient and sustainable reusability of enzymes in industrial settings.

Substrate Inhibition and Product Accumulation

In certain enzymatic reactions, the accumulation of reaction products or the presence of high substrate concentrations can lead to substrate inhibition, where the enzyme's activity is hindered by the excess substrate or product. This phenomenon can impede the reusability of enzymes by affecting their catalytic efficiency and necessitating additional steps to mitigate substrate inhibition, such as product removal or substrate dilution. Overcoming substrate inhibition and product accumulation is essential for maintaining the prolonged reusability of enzymes in industrial processes.

Enzyme Inactivation and Loss of Activity

Over successive reaction cycles, enzymes may undergo gradual inactivation or loss of activity due to factors such as surface fouling, chemical degradation, or mechanical stress. The cumulative effects of these phenomena can diminish the reusability of enzymes, requiring strategies for enzyme regeneration, rejuvenation, or replacement to sustain their catalytic performance over extended periods. Mitigating enzyme inactivation and preserving their activity are paramount in ensuring the long-term reusability of enzymes in industrial applications.

In navigating these challenges and limitations, ongoing research and innovation in enzyme engineering, bioprocess optimization, and bioreactor design are pivotal in enhancing the reusability of enzymes and expanding their potential across diverse industrial and environmental domains. By addressing these constraints, industries can harness the full benefits of enzyme reusability while advancing sustainable and efficient practices.

Conclusion

In conclusion, the reusability of enzymes stands as a cornerstone of sustainable industrial practices, offering a myriad of benefits across diverse sectors while presenting unique challenges that necessitate innovative solutions. The remarkable ability of enzymes to catalyze reactions with unparalleled specificity and efficiency, coupled with their inherent reusability, has positioned them as indispensable assets in driving innovation, enhancing productivity, and promoting environmental sustainability.

Throughout this exploration, we have delved into the mechanisms of enzyme reusability, uncovering the structural integrity, specificity, and regulatory control that underpin their repeated utilization. This inherent reusability not only contributes to cost-effectiveness but also aligns with the principles of sustainability by minimizing resource consumption and waste generation. Moreover, the industrial applications of enzymes span a wide spectrum of sectors, including food and beverage production, textile processing, biofuel development, pharmaceutical manufacturing, and environmental remediation, showcasing the versatility and efficacy of enzymes in optimizing processes and minimizing environmental impact.

Furthermore, the environmental benefits of enzymes, ranging from biodegradation and pollution remediation to reduced chemical usage and energy efficiency, underscore their pivotal role in fostering eco-friendly practices and mitigating the ecological footprint of human activities. However, it is essential to acknowledge the challenges and limitations associated with enzyme reusability, including stability under operational conditions, immobilization strategies, substrate inhibition, and enzyme inactivation, which necessitate ongoing research and innovation to maximize the potential of enzymes in industrial applications.

In navigating these challenges, the convergence of scientific advancements, bioprocess optimization, and sustainable engineering practices holds the key to unlocking the full potential of enzyme reusability. By addressing these constraints, industries can harness the catalytic prowess and eco-friendly attributes of enzymes to drive sustainable practices, minimize environmental impact, and foster a harmonious coexistence with the natural world.

Ultimately, the reusability of enzymes transcends beyond a mere industrial attribute; it embodies a paradigm of sustainable innovation and responsible stewardship of natural resources. As industries continue to embrace the transformative potential of enzymes, the journey towards a more sustainable and efficient industrial landscape is propelled, paving the way for a future where economic prosperity harmonizes with environmental preservation.