Home>Science & Environment>Operating Principle Of Float-Type Carburetors: Understanding The Key Mechanism

Science & Environment

Operating Principle Of Float-Type Carburetors: Understanding The Key Mechanism

Published: February 19, 2024

Learn the operating principle of float-type carburetors and understand the key mechanism. Explore the science and environmental impact of this essential automotive component.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Temperatures.com, at no extra cost. Learn more)

Table of Contents

Introduction

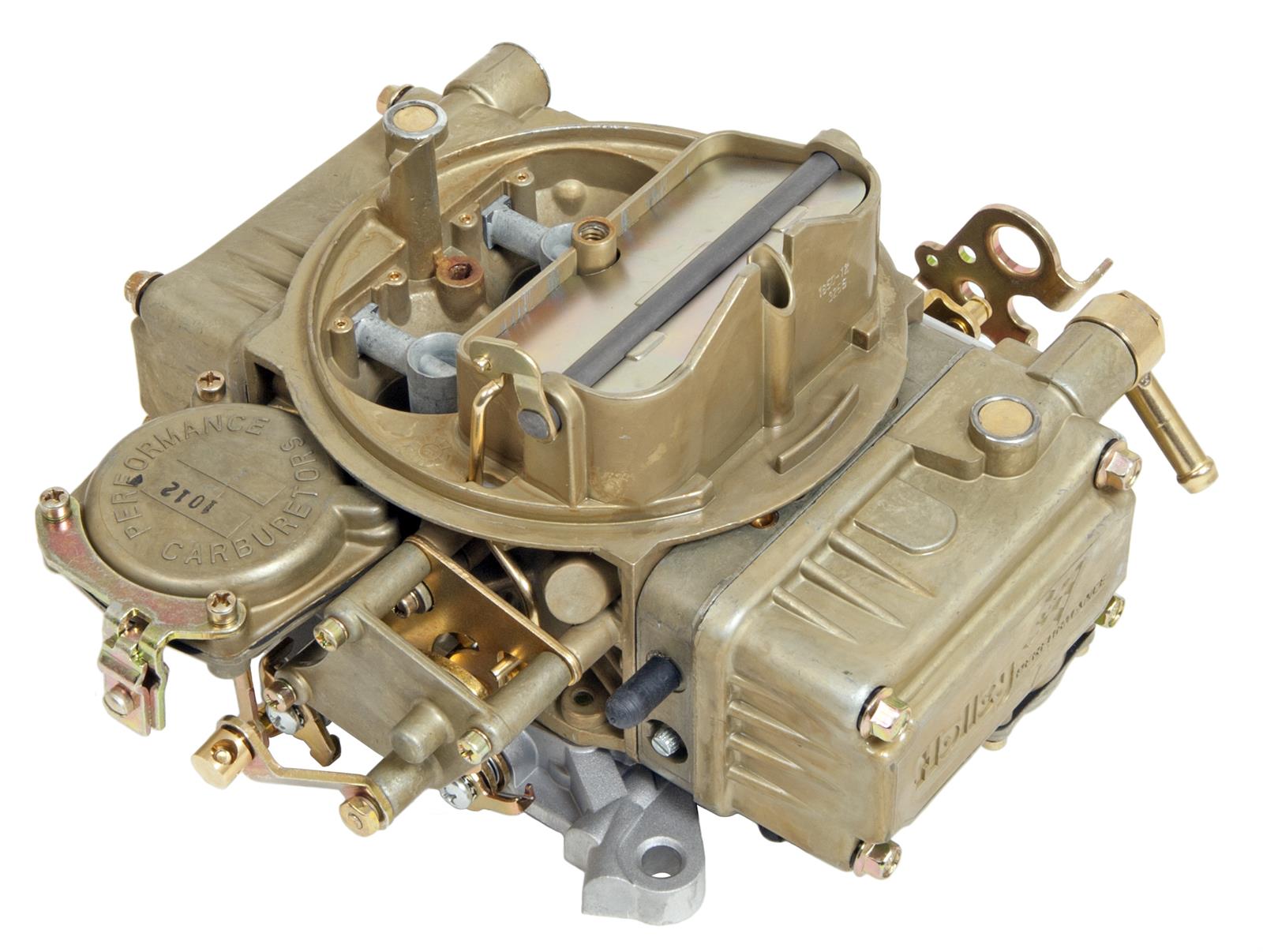

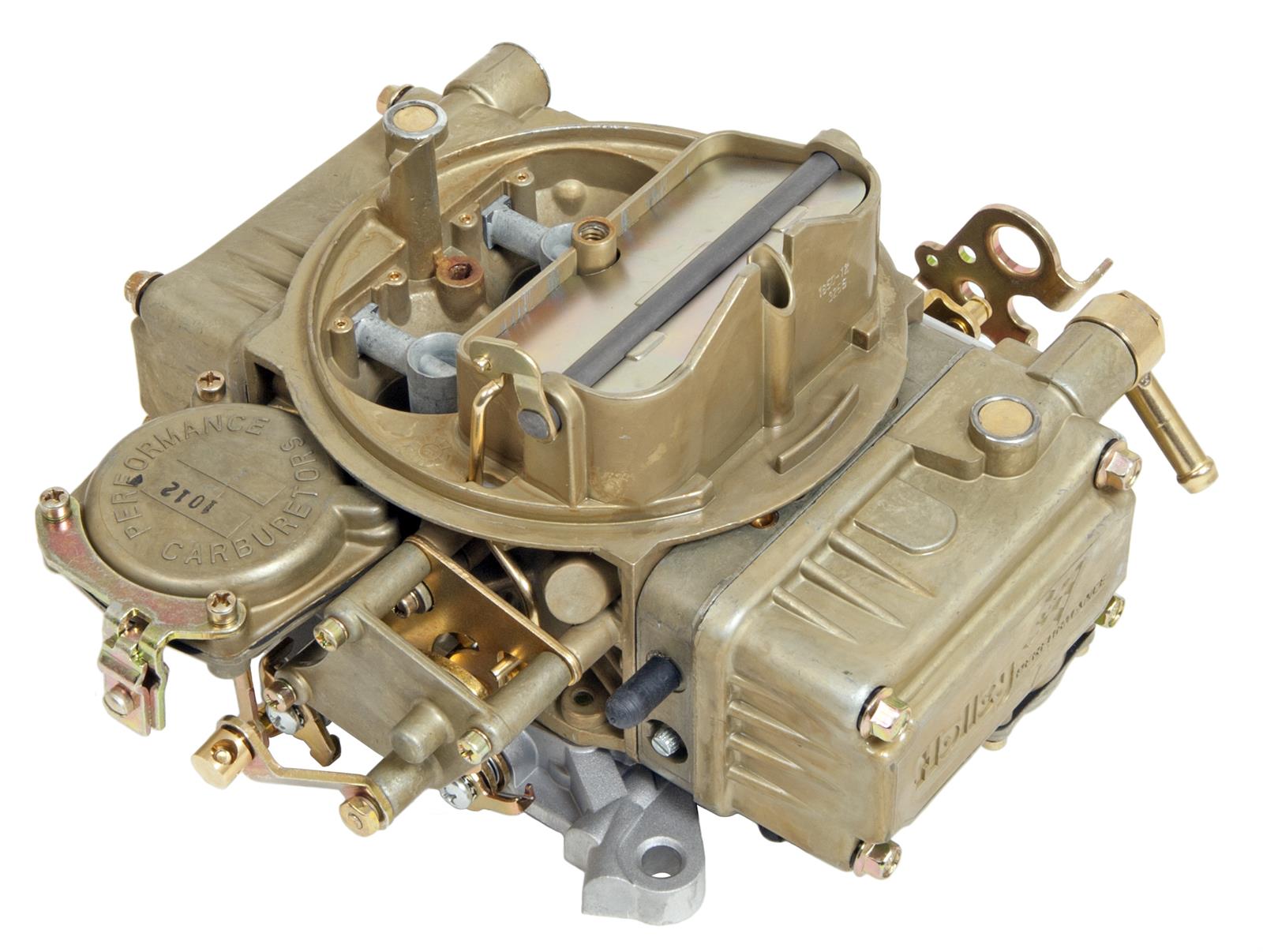

Float-type carburetors have been an integral part of internal combustion engines for decades, playing a crucial role in the fuel delivery system. Understanding the operating principle of float-type carburetors is essential for anyone interested in the mechanics of engines, whether for automotive, marine, or small engine applications.

These carburetors are designed to mix air and fuel in the correct proportion before delivering it to the engine for combustion. While modern vehicles often use fuel injection systems, float-type carburetors remain a fundamental component in many small engines, such as those found in lawnmowers, motorcycles, and chainsaws.

In this article, we will delve into the intricate workings of float-type carburetors, exploring their key mechanisms, components, and operational principles. By gaining a comprehensive understanding of these carburetors, readers will be better equipped to appreciate their significance in engine performance and troubleshoot common issues that may arise.

Let's embark on a journey to unravel the inner workings of float-type carburetors, shedding light on their role in the heart of internal combustion engines.

The Function of Float-Type Carburetors

Float-type carburetors serve a critical function in the operation of internal combustion engines by precisely mixing air and fuel to create a combustible mixture. This process is essential for the efficient and reliable performance of various types of engines, from small-scale applications to larger automotive and marine engines.

The primary function of a float-type carburetor is to deliver the correct air-fuel mixture to the engine under varying operating conditions. This is achieved through a delicate balance of airflow and fuel delivery, ensuring optimal combustion within the engine cylinders. The carburetor accomplishes this by utilizing the principles of Bernoulli's equation and the venturi effect.

When the engine is running, air is drawn into the carburetor through the air intake. As the air passes through the narrowest part of the carburetor, known as the venturi, its velocity increases, creating a region of low pressure. This low-pressure area causes fuel to be drawn from the carburetor's fuel bowl through the main jet, where it mixes with the incoming air to form a combustible mixture.

The float mechanism within the carburetor plays a crucial role in regulating the fuel level within the fuel bowl. As fuel is consumed by the engine, the float, typically made of a buoyant material such as plastic or brass, descends, opening the inlet valve to allow more fuel into the bowl. Once the fuel reaches a predetermined level, the float rises, closing the inlet valve to prevent overfilling.

By maintaining a consistent fuel level, the float mechanism ensures that the carburetor can deliver a steady supply of fuel to meet the engine's demands. This function is vital for engine operation, as an incorrect fuel-air mixture can lead to poor performance, increased emissions, and potential damage to engine components.

In essence, the function of float-type carburetors revolves around the precise regulation of the air-fuel mixture, enabling engines to operate efficiently across a range of conditions. Understanding this fundamental function is key to appreciating the role of carburetors in the performance and reliability of internal combustion engines.

Understanding the Key Mechanism

The key mechanism of float-type carburetors lies in their ability to precisely control the air-fuel mixture, a fundamental requirement for efficient engine operation. At the heart of this mechanism is the intricate interplay of several components, each playing a crucial role in the carburetor's functionality.

One of the central components is the float assembly, which consists of a float, a float chamber, and an inlet valve. The float, often made of a buoyant material such as plastic or brass, is positioned within the float chamber and is designed to rise and fall with the fuel level. As fuel is consumed by the engine, the float descends, opening the inlet valve to allow more fuel into the chamber. Once the fuel reaches a predetermined level, the float rises, closing the inlet valve to prevent overfilling. This mechanism ensures a consistent fuel level within the carburetor, enabling it to deliver the correct fuel-air mixture to the engine.

Another critical component is the venturi, a narrow section in the carburetor where the airflow velocity increases, creating a region of low pressure. This low-pressure area draws fuel from the carburetor's fuel bowl through the main jet, where it mixes with the incoming air to form a combustible mixture. The size and design of the venturi directly impact the carburetor's ability to regulate the air-fuel mixture, making it a key element in the mechanism.

Additionally, the throttle valve, connected to the accelerator pedal, controls the airflow into the carburetor. As the throttle valve opens and closes, it adjusts the amount of air entering the carburetor, thereby influencing the air-fuel mixture. This dynamic control allows the carburetor to respond to changes in engine load and speed, ensuring that the engine receives the appropriate fuel supply for optimal performance.

The intricate interplay of these components forms the foundation of the key mechanism behind float-type carburetors. By regulating the fuel level, controlling airflow, and facilitating the mixing of air and fuel, these carburetors play a pivotal role in delivering the precise air-fuel mixture required for efficient engine operation.

Understanding this key mechanism provides valuable insight into the inner workings of float-type carburetors, highlighting their significance in the broader context of internal combustion engines. This knowledge serves as a foundation for troubleshooting and maintaining carburetors, ultimately contributing to the reliable performance of engines across various applications.

Components of Float-Type Carburetors

Float-type carburetors consist of several essential components that work together to regulate the air-fuel mixture and ensure optimal engine performance. Understanding these components is crucial for comprehending the inner workings of carburetors and their role in the operation of internal combustion engines.

-

Float Assembly: The float assembly includes a float, float chamber, and inlet valve. The float, typically made of a buoyant material such as plastic or brass, is positioned within the float chamber. Its primary function is to regulate the fuel level within the carburetor. As fuel is consumed, the float descends, opening the inlet valve to allow more fuel into the chamber. Once the fuel reaches the desired level, the float rises, closing the inlet valve to prevent overfilling. This mechanism ensures a consistent fuel level, crucial for delivering the correct air-fuel mixture to the engine.

-

Venturi: The venturi is a critical component that influences the carburetor's ability to regulate the air-fuel mixture. It is a narrow section where the airflow velocity increases, creating a low-pressure area. This low pressure draws fuel from the carburetor's fuel bowl through the main jet, where it mixes with the incoming air to form a combustible mixture. The design and size of the venturi directly impact the carburetor's performance in controlling the air-fuel ratio.

-

Throttle Valve: Connected to the accelerator pedal, the throttle valve controls the airflow into the carburetor. As the throttle valve opens and closes, it adjusts the amount of air entering the carburetor, thereby influencing the air-fuel mixture. This dynamic control allows the carburetor to respond to changes in engine load and speed, ensuring that the engine receives the appropriate fuel supply for optimal performance.

-

Main Jet and Idle Jet: These jets are responsible for delivering fuel into the venturi under different operating conditions. The main jet supplies fuel during normal engine operation, while the idle jet provides fuel when the engine is idling. The size of these jets directly affects the air-fuel mixture, making them crucial components in the carburetor's functionality.

-

Choke Mechanism: The choke is designed to enrich the air-fuel mixture during cold starts. By restricting the airflow, the choke increases the fuel concentration, aiding in the engine's initial ignition. As the engine warms up, the choke gradually opens to allow for normal operation.

Understanding the roles and interactions of these components provides valuable insight into the intricate workings of float-type carburetors. Each component plays a vital role in regulating the air-fuel mixture, ensuring efficient engine operation across various conditions and loads.

How Float-Type Carburetors Work

Float-type carburetors operate on a precise and intricate mechanism to deliver the optimal air-fuel mixture required for efficient engine performance. Understanding the inner workings of these carburetors provides valuable insight into their role in the operation of internal combustion engines.

When the engine is running, air is drawn into the carburetor through the air intake. As the airflow enters the narrowest part of the carburetor, known as the venturi, its velocity increases, creating a region of low pressure. This low-pressure area effectively draws fuel from the carburetor's fuel bowl through the main jet, where it mixes with the incoming air to form a combustible mixture.

The float assembly, a central component of the carburetor, plays a crucial role in regulating the fuel level within the fuel bowl. Consisting of a float, float chamber, and inlet valve, the float is designed to rise and fall with the fuel level. As fuel is consumed by the engine, the float descends, opening the inlet valve to allow more fuel into the bowl. Once the fuel reaches a predetermined level, the float rises, closing the inlet valve to prevent overfilling. This mechanism ensures a consistent fuel level, enabling the carburetor to deliver the correct air-fuel mixture to the engine.

The throttle valve, connected to the accelerator pedal, controls the airflow into the carburetor. By adjusting the amount of air entering the carburetor, the throttle valve influences the air-fuel mixture, allowing the carburetor to respond to changes in engine load and speed. This dynamic control ensures that the engine receives the appropriate fuel supply for optimal performance.

In addition to the main jet, float-type carburetors also incorporate an idle jet, which provides fuel when the engine is idling. These jets play a crucial role in delivering the correct air-fuel mixture under different operating conditions, contributing to the overall functionality of the carburetor.

The choke mechanism, another essential component, enriches the air-fuel mixture during cold starts by restricting the airflow. This enrichment aids in the engine's initial ignition, ensuring smooth operation during cold conditions. As the engine warms up, the choke gradually opens to allow for normal operation.

By regulating the fuel level, controlling airflow, and facilitating the mixing of air and fuel, float-type carburetors play a pivotal role in delivering the precise air-fuel mixture required for efficient engine operation. This intricate process ensures that engines can operate reliably across a range of conditions, making float-type carburetors a fundamental component in the realm of internal combustion engines.

Common Issues and Troubleshooting

Float-type carburetors, while integral to the operation of internal combustion engines, can experience various issues that affect engine performance. Understanding these common issues and their troubleshooting methods is essential for maintaining the functionality of carbureted engines.

-

Fuel Contamination: Contaminated fuel can lead to clogging of the carburetor's jets and passages, resulting in poor engine performance. To troubleshoot this issue, it is crucial to drain the fuel system, clean the carburetor thoroughly, and replace the fuel filter. Additionally, using high-quality, clean fuel is essential for preventing future contamination.

-

Float Level: Incorrect float level can cause fuel overflow or insufficient fuel delivery, leading to engine stalling or flooding. Troubleshooting this issue involves adjusting the float level according to the manufacturer's specifications, ensuring that the float assembly operates within the designated parameters.

-

Air Leaks: Air leaks in the carburetor or its gaskets can disrupt the air-fuel mixture, causing erratic engine operation. Troubleshooting involves inspecting and replacing damaged gaskets, ensuring a proper seal between carburetor components to prevent air leaks.

-

Clogged Jets: Accumulation of debris or varnish in the carburetor's jets can impede fuel flow, resulting in lean fuel mixtures and engine hesitation. Troubleshooting this issue requires disassembling the carburetor and meticulously cleaning the jets and passages to restore proper fuel delivery.

-

Idle Issues: Irregular or unstable idling can stem from incorrect idle adjustments or clogged idle circuits. Troubleshooting involves adjusting the idle speed and mixture screws to the manufacturer's specifications and cleaning the idle circuits to ensure smooth idling.

-

Choke Malfunction: A malfunctioning choke can lead to difficulties in cold starting and poor initial engine operation. Troubleshooting this issue involves inspecting the choke mechanism, ensuring proper operation, and adjusting it for optimal enrichment during cold starts.

-

Throttle Linkage Problems: Issues with the throttle linkage can result in poor throttle response and uneven acceleration. Troubleshooting involves inspecting and lubricating the throttle linkage, ensuring smooth and responsive operation.

-

Worn Components: Over time, wear and tear can affect various carburetor components, leading to degraded performance. Troubleshooting involves inspecting for worn parts such as throttle shafts, seals, and gaskets, and replacing them as necessary to restore optimal functionality.

By addressing these common issues through effective troubleshooting methods, engine enthusiasts and mechanics can ensure the reliable performance of float-type carburetors, contributing to the smooth operation of carbureted engines across diverse applications.

Conclusion

In conclusion, the operating principle of float-type carburetors represents a fundamental aspect of internal combustion engines, playing a pivotal role in regulating the air-fuel mixture to ensure efficient engine performance. Through the intricate interplay of components such as the float assembly, venturi, throttle valve, and various jets, float-type carburetors facilitate the precise delivery of fuel to meet the engine's demands across varying operating conditions.

Understanding the key mechanism of float-type carburetors provides valuable insight into their significance in the broader context of engine operation. The delicate balance maintained by the float assembly, regulating the fuel level within the carburetor, underscores the critical role of these components in delivering the correct air-fuel mixture. Additionally, the dynamic control exerted by the throttle valve and the enrichment provided by the choke mechanism further highlight the comprehensive functionality of float-type carburetors.

Moreover, the identification and troubleshooting of common issues associated with float-type carburetors are essential for maintaining the reliability and performance of carbureted engines. Addressing fuel contamination, float level adjustments, air leaks, clogged jets, idle issues, choke malfunctions, throttle linkage problems, and worn components through effective troubleshooting methods are crucial steps in ensuring the seamless operation of float-type carburetors and, by extension, the engines they serve.

As modern engine technologies continue to evolve, fuel injection systems have become prevalent, gradually replacing traditional carburetors in many automotive applications. However, float-type carburetors remain integral in various small-scale engines, including those found in lawnmowers, motorcycles, and chainsaws. Their enduring significance underscores the enduring relevance of understanding and appreciating the operating principles of these carburetors.

In essence, the comprehensive understanding of float-type carburetors, encompassing their key mechanism, components, operational principles, and troubleshooting methods, empowers enthusiasts and mechanics to uphold the reliability and performance of carbureted engines. This knowledge serves as a testament to the enduring legacy of float-type carburetors in the realm of internal combustion engines, cementing their place as a cornerstone of mechanical ingenuity and engineering excellence.